How to Correctly Cut PEEK Tubing Using the Clean‑Cut90™ Cutter

A clean, square, burr‑free cut is absolutely essential for all HPLC tubing, including PEEK. Poorly cut tubing introduces extra‑column volume, causes fitting leaks, increases band broadening, and results in unstable or inconsistent chromatographic performance.

The ARE-Applied Research brand, Clean‑Cut90™ tubing cutter is specifically engineered to produce a proper 90° end‑face, ensuring reliable sealing and optimal flow characteristics.

Why Cutting Accuracy Matters in HPLC

PEEK tubing is soft compared to stainless steel, making it extremely sensitive to angled cuts or rough edges. Even small deviations from perpendicular can result in:

- Misalignment inside fittings

- Poor ferrule seating

- Dead‑volume pockets

- Flow disturbances and peak distortion

- Leaks under pressure

A consistent 90° end prevents these issues and maintains column efficiency.

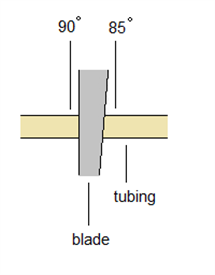

Understanding the Clean‑Cut90™ Blade

The Clean‑Cut90™ cutter contains a two‑sided blade, and only one side produces the correct 90° cut. This is why orientation is critical.

Blade Features

-

90° Cutting Side

- Marked by an embossed arrow on the tool

- Must face the tubing end you intend to cut

- Produces the perpendicular cut required for HPLC

-

85° Cutting Side

- Located on the opposite side

- Creates a slanted cut unsuitable for HPLC use

- Should never be used when preparing tubing for an instrument

How to Use the Clean‑Cut90™ Correctly

-

Identify the correct blade side

Look for the embossed arrow—this indicates the 90° cutting surface. -

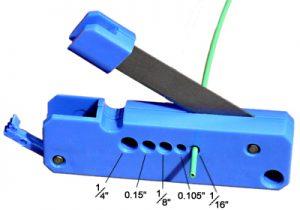

Insert PEEK tubing into the correct diameter hole

The tool provides five OD‑size options:

- 1/4″

- 0.15″

- 1/8″

- 0.105″

- 1/16″

Tubing should fit snugly to avoid angled cuts.

- Cut in one clean, downward motion

- A smooth, decisive cut prevents crushing or deformation.

- Inspect the cut end

- Ensure it is square, smooth, and free from burrs.

Beware of Improper Tubing Cutters

Not all tubing cutters are designed for chromatography. MICROSOLV notes that many third‑party tools produce:

- 86° cuts, even on both sides

- Uneven or rough faces

- Deformation of the tubing during cutting

- Inconsistent performance under pressure

Such cutters may cause subtle, hard‑to‑diagnose chromatographic problems.

Why the Clean‑Cut90™ Is Recommended

- Produces true 90° end‑faces

- Prevents leaks and dead volume

- Protects fittings and ferrules from damage

- Ensures reproducible connections and retention times

- Supports all common HPLC PEEK tubing ODs

It is specifically engineered for precision laboratory tubing preparation.

Conclusion

Accurate tubing preparation is fundamental to reliable HPLC performance. Using the Clean‑Cut90™ cutter ensures every cut is clean, perpendicular, and ready for leak‑free, low‑volume connections. Proper cutting technique eliminates one of the most common hidden causes of poor chromatography and preserves the integrity of your instrument’s flow path.

For ordering information, provides dedicated Clean‑Cut90™ product details.

In order to get the best cut, you need to use the hole that is designated for the correct diameter tubing. The tubing cutter is equipped with holes to accommodate five different tubing ODs: 1/4", 0.15", 1/8", 0.105", and 1/16". The tubing should fit snugly in the appropriate hole . In the picture above, the indicating arrow is not shown and is on the opposite side of the cutter displayed.

Click HERE for ordering information of the Clean Cut 90.