Understanding Pre‑Cut Stainless Steel Tubing for HPLC Systems

Accurate, contamination‑free tubing connections are essential to maintaining chromatographic integrity in any HPLC or LC‑MS system. MICROSOLV’s pre‑cut stainless steel (SS) tubing is designed specifically to address one of the most persistent challenges in chromatography labs: producing consistently square, burr‑free cuts that ensure zero dead‑volume connections between system components.

Improperly cut tubing can introduce dead volume, turbulence, leaks, and peak distortion. Pre‑cut tubing eliminates these risks by providing precision‑cut sections that are ready to install.

Precision Manufacturing for Maximum Performance

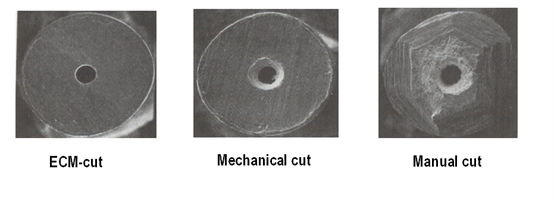

ARE-Applied Research brand of pre‑cut SS tubing is manufactured using Electronic Discharge Cutting (EDC/ECM) technology. This automated method produces:

- Perfectly square tubing ends

- Consistent internal diameter (ID) and outer diameter (OD)

- Burr‑free surfaces suitable for high‑pressure sealing

- Zero‑dead‑volume engagement with common HPLC fittings

These machining improvements lead to more stable baselines, reduced band broadening, and fewer instrument‑induced artifacts.

All tubing sections are also welded and annealed for durability and pressure stability, ensuring predictable behavior under high‑pressure LC conditions.

Available Dimensions and Color‑Code Identification

WE offer pre‑cut tubing in a wide range of IDs, ODs, and lengths to support different instrument geometries and flow requirements.

Common ID Options (color‑coded)

- 0.005” ID – Red band

- 0.007” ID – Black band

- 0.040” ID – No band for this size

Standard OD

- 1/16 inch (1.60 mm) across all listed models

Common Lengths

- 5 cm, 10 cm, 20 cm, 30 cm, 50 cm

These sizes allow users to select the optimal tubing span required to minimize system dwell volume while maintaining flexibility in system layout.

Dimensional Accuracy and Tolerances

To support high‑accuracy analytical work, ARE-Applied Researach brand of pre‑cut SS tubing is manufactured to strict tolerances:

- ID/OD tolerance: ±0.05 mm

- Wall thickness varies by ID (e.g., 0.287–0.731 mm depending on style)

These engineered tolerances ensure compatibility with standard compression fittings and ferrules, reducing the likelihood of leaks or improper seating.

Application Advantages in HPLC & LC‑MS

Using pre‑cut stainless steel tubing provides several key benefits:

1. Guaranteed Zero Dead Volume

Burr‑free cuts ensure perfect mating surfaces with unions, reducing dispersion and improving signal integrity—especially important for LC‑MS trace analysis.

2. Eliminates the Need for Manual Cutting

Manual cutting of SS tubing is notoriously difficult and often leads to angled cuts, burrs, crushed tubing, or micro‑fractures. Pre‑cut sections guarantee consistent quality every time.

3. Improved Reproducibility Across Instruments

Consistent tubing reduces variability between system setups, ensuring reproducible retention times and more stable gradients.

4. Enhanced System Reliability

Properly manufactured tubing reduces chances of leaks, clogging, and pump backpressure spikes.

Choosing the Right Tubing for Your Method

When selecting a pre‑cut SS tubing segment, consider:

- ID: Smaller IDs (<0.010”) are ideal for low‑flow methods, micro‑LC, and high sensitivity LC‑MS. Larger IDs support semi‑prep or high‑flow applications.

- Length: Choose the shortest length achievable while allowing proper routing—minimizing dwell volume improves gradient fidelity.

- Color coding: Use band color to avoid ID selection mistakes during installation.

Conclusion

ARE-Applied Research brand of pre‑cut stainless steel tubing provides a precise, reliable, and efficient solution for chromatographers who require consistent performance without the hassle of manual cutting. With EDC‑machined, burr‑free ends and strict dimensional tolerances, these pre‑cut sections ensure robust connections and optimal chromatographic results.

Click HERE for high pressure tubing ordering information and pictures.