Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, 1 meter roll, ARE-Applied Research brand. 1 EA.

We operate globally and use cookies, including for analytics and personalization to improve your experience on our site. To find out more, read our updated Privacy policy

Click HERE for FAQ (Frequently Asked Questions) about Tubing for the Laboratory.

Click HERE for PEEK Tubing Specifications.

No Application Notes information

Our goal is to provide the best Customer Experience possible. If you cannot find what you are looking for, have any questions or would like to give us a suggestion please use any of the following ways to contact us directly. We would love to hear from you.

Call us: 8:30AM - 6:00PM EST 1-732-380-8900 and hit 0#

Fax to us: 1-910-769-9435

Email Customer Support

We are always ready to lend any support we can. Our experienced scientists and professionals are ready to assist you with any technical support questions. Every question is considered a good question and we will work with you on a solution as fast as possible.

Call us: 8:30AM - 6:00PM EST 1-732-380-8900 and hit 0#

Fax to us: 1-910-769-9435

Email Technical Support

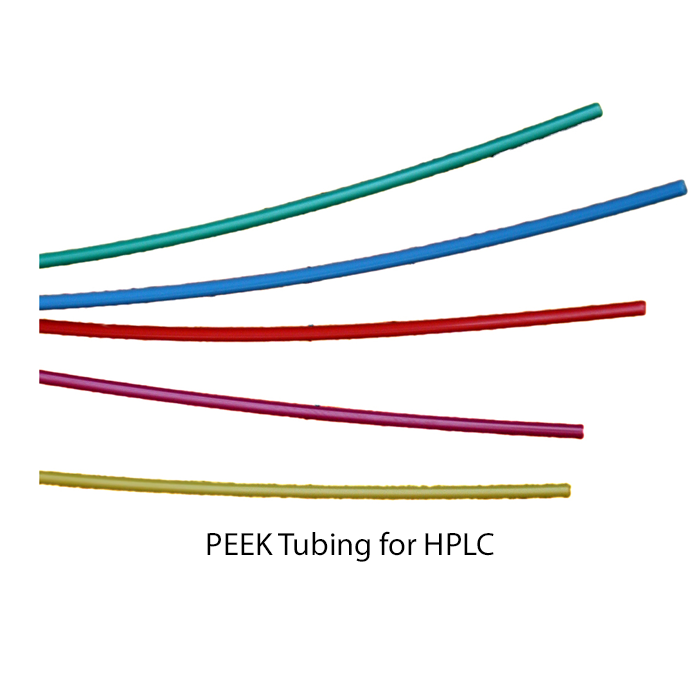

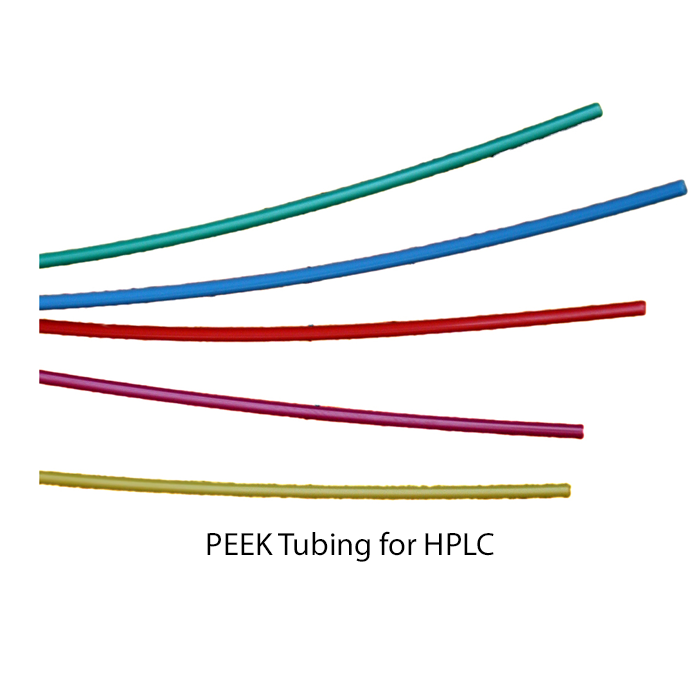

PEEK tubing | Various ID and OD sizes. High pressure zones.

Our PEEK thermoplastic tubing is extruded from virgin PEEK and has excellent chemical resistance, low adsorption rate and great dimensional stability. PEEK is generally considered biocompatible thanks to its optimal modulus. We do not add any additives to the original PEEK material except for color particles in the solid-color tubing and the striped tubing color is co-extruded so the color is on the outside only of the tubing.

PEEK is used as an alternative to stainless steel tubing in HPLC and other fields due to its mechanical strength. Click HERE to view specifications.

Solid colored PEEK tubing is common for everyday use in HPLC as its chemically resistant and flexible. Tolerance is +/- 0.05mm for both ID and OD. Most economical

Striped colored indicator PEEK tubing consists of natural PEEK with a color stripe added to the outside only of the tubing after extrusion. We recommend using striped or natural tubing, as PEEK is not stable to all chemicals. Some solvents may react with the PEEK wall material and dissolve the color particles; this is an indication the tubing should be replaced. Tolerance is +/- 0.05mm for both ID and OD.

Ultra-T™ PEEK tubing is recommended when the flow volume precision is desired and is critical. This tubing is not normally used in typical HPLC systems; it is mostly used for LCMS, capillary LC and other applications that allow for little variation in flow dynamics. Tolerance is +/- 0.025mm for both ID and OD.

FlexiTubes coiled tubing for HPLC pulse dampener. Click HERE for ordering information.

Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.0025 inch (0.064 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, red intermittent stripes, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, red intermittent stripes, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, red intermittent stripes, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, red intermittent stripes, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, red intermittent stripes, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, Pre-Cut, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) ID, Ultra-T grade, red intermittent stripes, 10 cm long (+/- 1 mm). ARE-Applied Research brand. 5 PK.

Tubing, PEEK, Pre-Cut, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) ID, Ultra-T grade, red intermittent stripes, 20 cm long (+/- 1 mm). ARE-Applied Research brand. 5 PK.

Tubing, PEEK, Pre-Cut, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) ID, Ultra-T grade, red intermittent stripes, 30 cm long (+/- 1 mm). ARE-Applied Research brand. 5 PK.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, yellow intermittent stripes, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, yellow intermittent stripes, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, yellow intermittent stripes, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, yellow intermittent stripes, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, yellow intermittent stripes, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, yellow intermittent stripes, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, Pre-Cut, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 10 cm (+/- 1 mm). ARE-Applied Research brand. 5 PK.

Tubing, PEEK, Pre-Cut, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 20 cm long (+/- 1 mm). ARE-Applied Research brand. 5 PK.

Tubing, PEEK, Pre-Cut, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, Ultra-T grade, blue intermittent stripes, 30 cm long (+/- 1 mm). ARE-Applied Research brand. 5 PK.

Tubing, Capillary, PEEK, 75 um ID, 360 um OD, natural color, 1 meter roll. ARE-Applied Research brand. 1 EA.

Tubing, Capillary, PEEK, 75 um ID, 360 um OD, natural color, 3 meter roll. ARE-Applied Research brand. 1 EA.

Tubing, Capillary, PEEK, 75 um ID, 360 um OD, natural color, 5 meter roll. ARE-Applied Research brand. 1 EA.

Tubing, Capillary, PEEK, 75 um ID, 360 um OD, natural color, 10 Meter Roll. ARE-Applied Research brand. 1 EA.

Tubing, Capillary, PEEK, 75 um ID, 360 um OD, natural color, 25 Meter Roll. ARE-Applied Research brand. 1 EA.

Tubing, Capillary, PEEK, 75 um ID, 360 um OD, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, red stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, red stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, red stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, red stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, red stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, red stripe, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid red, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid red, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid red, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid red, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid red, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid red, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, yellow stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, yellow stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, yellow stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, yellow stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, yellow stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, yellow stripe, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid yellow, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid yellow, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid yellow, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid yellow, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid yellow, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid yellow, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, blue stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, blue stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, blue stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, blue stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, blue stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, blue stripe, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid blue, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid blue, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid blue, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid blue, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid blue, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid blue, Your continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, orange stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, orange stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, orange stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, orange stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, orange stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, orange stripe. Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid orange, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid orange, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid orange, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid orange, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid orange, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.020 inch (0.50 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid orange, Your continuous length tubing. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, green stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, green stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, green stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, green stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, green stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, green stripe. Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid green, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid green, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid green, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid green, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid green, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/16th inch (1.6 mm) OD, general grade, solid green, Your continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.040 inch (1.0 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, grey stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.040 inch (1.0 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, grey stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.040 inch (1.0 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, grey stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.040 inch (1.0 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, grey stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.040 inch (1.0 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, grey stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.040 inch (1.0 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, grey stripe, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.055 inch (1.4 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, black stripe, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.055 inch (1.4 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, black stripe, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.055 inch (1.4 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, black stripe, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.055 inch (1.4 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, black stripe, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.055 inch (1.4 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, black stripe, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.055 inch (1.4 mm) ID, 1/16th inch (1.6 mm) OD, HPLC grade, black stripe, Your custom continous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 1/16th inch (1.6 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/16th inch (1.6 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/16th inch (1.6 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/16th inch (1.6 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/16th inch (1.6 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/16th inch (1.6 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 1/8th inch (3.2 mm) ID, 1/4th inch (6.35 mm) OD, HPLC grade, natural color, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/8th inch (3.2 mm) ID, 1/4th inch (6.35 mm) OD, HPLC grade, natural color, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/8th inch (3.2 mm) ID, 1/4th inch (6.35 mm) OD, HPLC grade, natural color, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/8th inch (3.2 mm) ID, 1/4th inch (6.35 mm) OD, HPLC grade, natural color, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/8th inch (3.2 mm) ID, 1/4th inch (6.35 mm) OD, HPLC grade, natural color, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 1/8th inch (3.2 mm) ID, 1/4th inch (6.35 mm) OD, HPLC grade, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.030 inch (0.75 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.080 inch (2.0 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.080 inch (2.0 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.080 inch (2.0 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.080 inch (2.0 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.080 inch (2.0 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.080 inch (2.0 mm) ID, 1/8th inch (3.2 mm) OD, HPLC grade, natural color, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.005 inch (0.13 mm) ID x 1/32nd inch (0.79 mm) OD, general grade, natural, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID x 1/32nd inch (0.79 mm) OD, general grade, natural, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID x 1/32nd inch (0.79 mm) OD, general grade, natural, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID x 1/32nd inch (0.79 mm) OD, general grade, natural, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID x 1/32nd inch (0.79 mm) OD, general grade, natural, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.005 inch (0.13 mm) ID x 1/32nd inch (0.79 mm) OD, general grade, natural, Your custom continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.007 inch (0.18 mm) ID, 1/32 inch (0.79 mm) OD, general grade, natural, Your continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 1 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 3 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/32 inch (0.79 mm) OD, general grade, natural, 5 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 10 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, 25 meter roll, ARE-Applied Research brand. 1 EA.

Tubing, PEEK, 0.010 inch (0.25 mm) ID, 1/32nd inch (0.79 mm) OD, general grade, natural, Your continuous length tubing, priced per meter. ARE-Applied Research brand.

Custom Order Item. Inquire for more information.

© Copyright 2026. MICROSOLV. All Rights Reserved. Website & Hosting by BlueTone Media